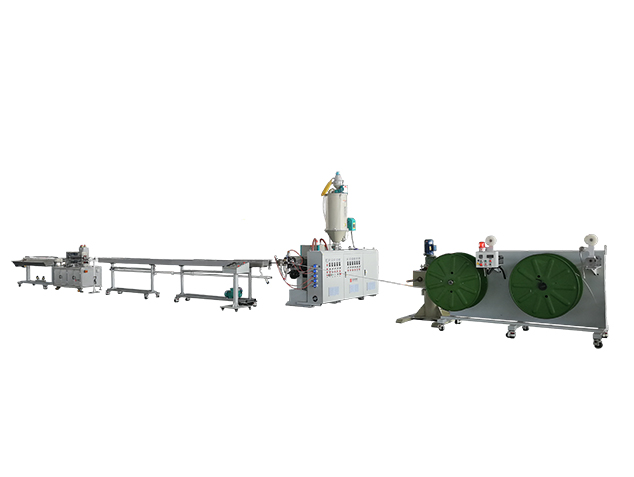

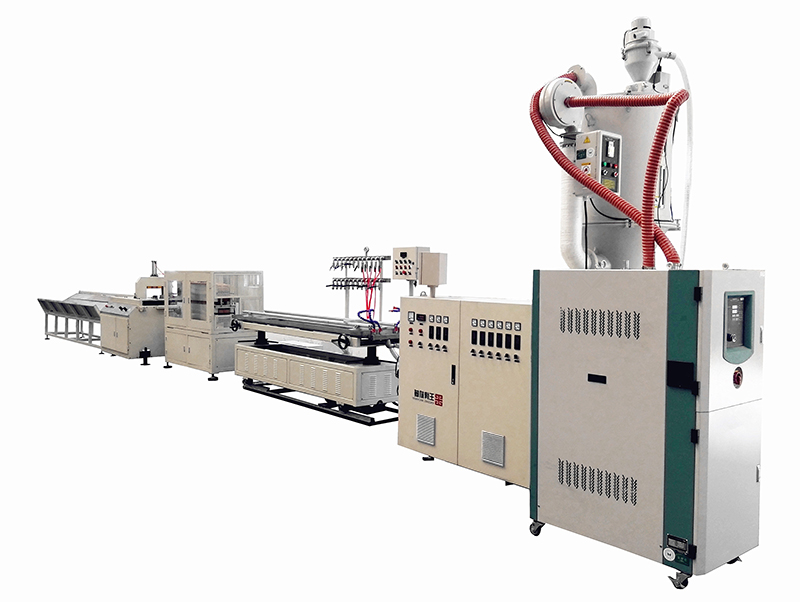

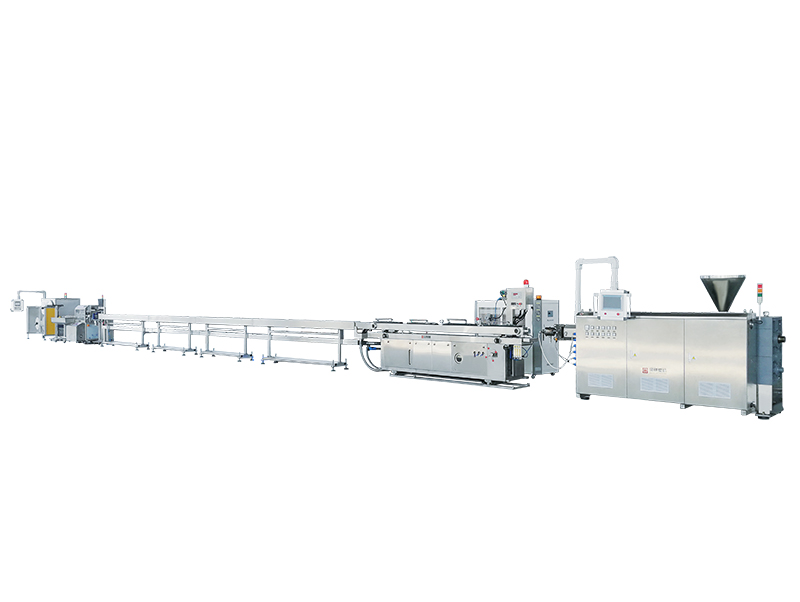

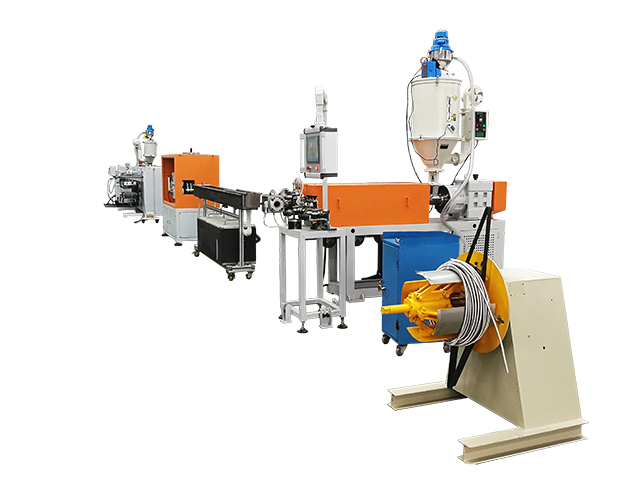

High-Quality 3D Printer Filament Extrusion Line for Efficient and Consistent Results

Introducing the cutting-edge 3D Printer Filament Extrusion Line, proudly presented by Jiangsu Baodie Automation Equipment Co., Ltd., a leading manufacturer and factory based in China. Designed to revolutionize the additive manufacturing industry, this state-of-the-art extrusion line is meticulously crafted to deliver top-notch performance and unmatched precision. Whether you are a DIY enthusiast or a professional in the field, our cutting-edge filament extrusion line guarantees to enhance your 3D printing experience to new heights. At Jiangsu Baodie Automation Equipment Co., Ltd., we are committed to delivering impeccable quality and utmost customer satisfaction. Our team of skilled engineers and technicians have meticulously engineered this advanced line, incorporating the latest technological innovations and superior materials. We pride ourselves on our expertise and dedication to staying at the forefront of the industry. As a reliable and renowned manufacturer and factory, we have gained a strong reputation for providing durable, efficient, and innovative machinery. Our 3D Printer Filament Extrusion Line exemplifies our commitment to excellence, ensuring seamless and reliable filament extrusion at every step. Elevate your 3D printing projects with our cutting-edge filament extrusion line, exclusively brought to you by Jiangsu Baodie Automation Equipment Co., Ltd., your trusted partner in China.

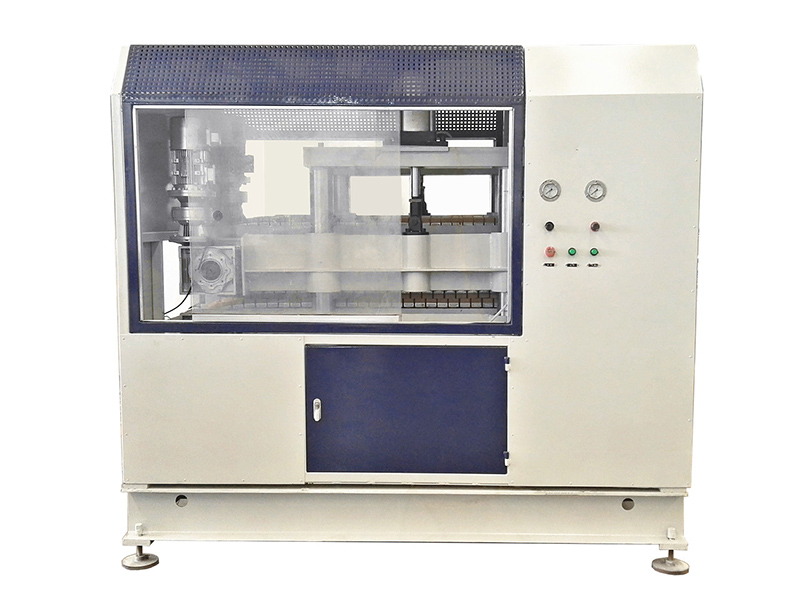

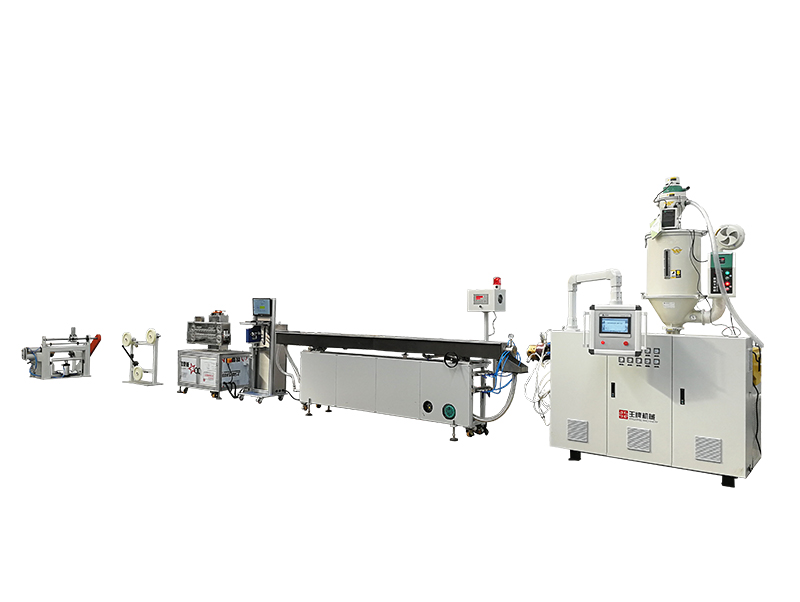

Related Products