Recently, a client team from overseas visited BAOD EXTRUSION for the on-site trial and acceptance of a custom TPU pneumatic tube extrusion line. The equipment operated smoothly with excellent performance, and the customer expressed strong satisfaction on-site.

Stable Operation, Reliable Performance

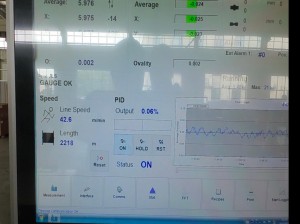

During the trial, the complete line—from material extrusion, vacuum sizing, and laser diameter monitoring to servo-driven pulling and final winding—was tested in full operation. All systems worked in sync, demonstrating the maturity and reliability of the entire setup.

Positive Customer Feedback

The client specifically acknowledged the following strengths:

· TPU-dedicated screw ensures uniform plasticization and stable output;

· Vacuum sizing and independent cooling improve dimensional accuracy;

· Laser diameter gauge integrated with closed-loop control keeps dimensions in check;

· Servo traction and constant tension winding ensure that the finished pipes are neat and free from deformation

Rigorous Quality Control, Confident Delivery

From design to final commissioning, BAOD maintains strict quality control across every stage to ensure the line is ready for stable production upon delivery—helping customers start faster and run smoother.

Exported Worldwide, Trusted by Industry

BAOD EXTRUSION lines are widely used in automotive, medical, and pneumatic industries, with successful installations across Europe, Southeast Asia, and the Middle East—earning long-term trust from global partners.

BAOD EXTRUSION

Focused on high-end plastic extrusion equipment. We welcome global partners to visit and collaborate.

Post time: Aug-12-2025